Facilities

The FabLab houses many tools and machines that researchers can utilize to create their projects. They include:

HAAS CM1 CNC MILLING MACHINE

The Computer Numerical Control (CNC) mill, commonly referred to as an automatic milling or cutting machine, is used for “sculpting” hard materials, and works off a 3D computer model. The FabLab houses a CM1 model, which can provide precise, 3D-milled parts from almost any material, including plastics and metals. The working volume of this machine is 300×250×300 mm.

For machine specs, please click here.

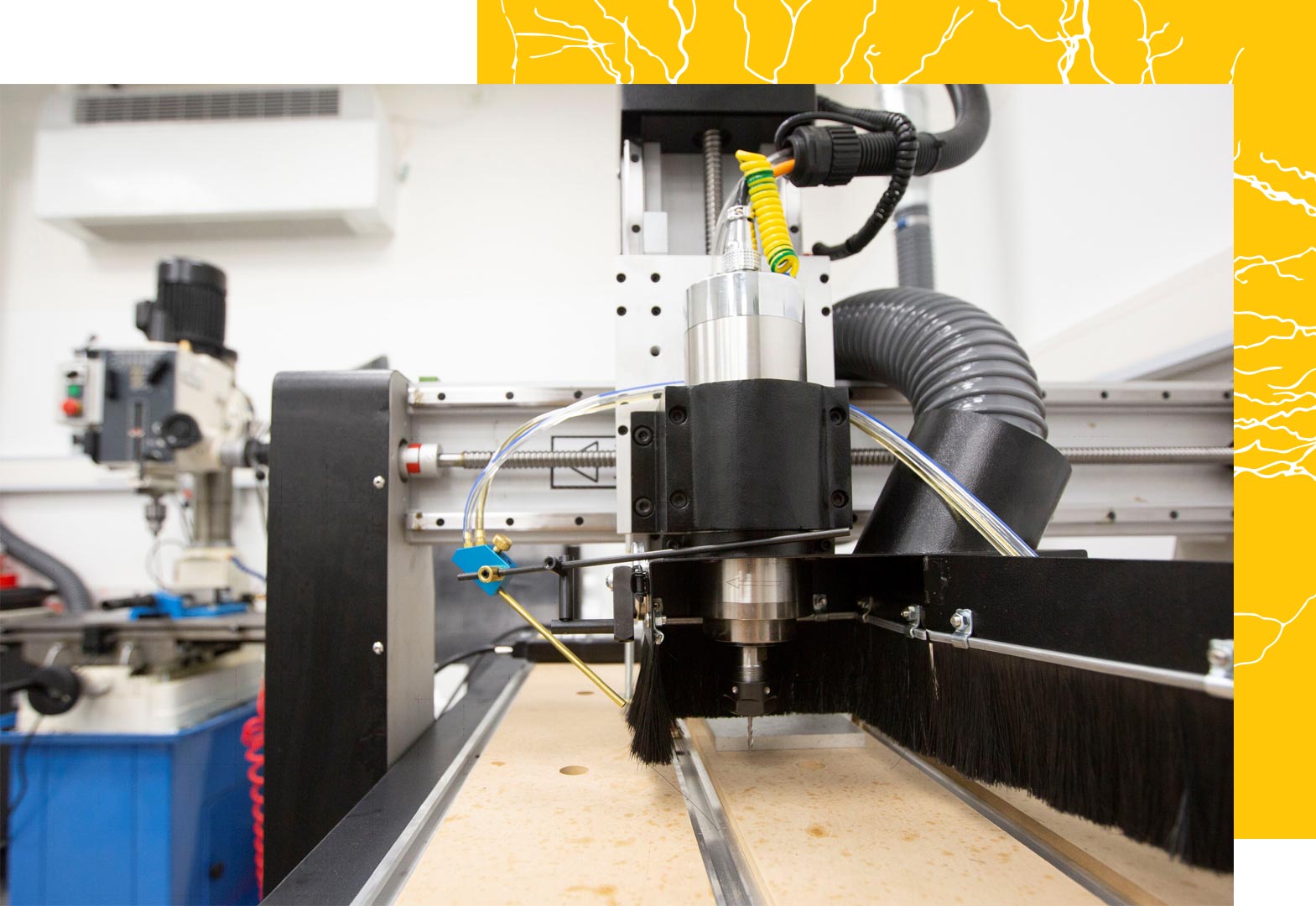

LAGUNA IQ CNC ROUTER MACHINE

This CNC machine is also used for cutting and 3D milling soft materials, such as plastics and aluminum sheets. Compared to the HAAS CM1, the Laguna machine can automatically manufacture larger and less precise products. The working volume of this machine is 600×900×150 mm.

For machine specs, please click here.

FORMLABS FORM 3

This machine is a Stereolithography (SLA) 3D printer for precise products. Transparent, rigid, elastic, autoclavable and biocompatible materials are available for this machine. The printing volume of this machine is 145×145×185 mm.

For machine specs, please click here.

PRUSA I3 MK3S

This machine is a Fused Filament Fabrication (FFF) 3D printer, and is commonly used for draft prototypes or end products. As this kind of printing creates the object by molding strings, the object’s structure is built with fibers (SLA printing uses a grain structure). Products of FFF printing can be more durable than the products of SLA printing. Another advantage is that the structure of the object can be almost hollow, resulting in lighter objects. The printing volume of this machine is 250×210×210 mm.

For machine specs, please click here.

ANALOG MACHINES AND TOOLS

The FabLab also owns a number of analog tools, including a lathe, band saw, press drills, and more.